9 Best CNC Learning Courses online reviewed

In today’s rapidly evolving world of manufacturing and engineering, precision and efficiency are paramount. Industries ranging from aerospace and automotive to electronics and prototyping demand highly accurate and intricate parts of complex machinery, and the need for skilled professionals who can operate computer numerical control (CNC) machines has never been greater.

CNC machining has revolutionized the manufacturing landscape, empowering designers and engineers to transform their ideas into tangible reality with unparalleled precision. If you’re intrigued by the prospect of delving into this exciting field or eager to upskill your existing knowledge, you’ve come to the right place.

In this article, we will explore the realm of the best CNC learning courses for machinists and unveil the best courses and options available to help you embark on a transformative journey. Whether you’re a complete beginner looking to understand the fundamentals or an experienced CNC machinist seeking advanced techniques to gain knowledge, these courses cater to a wide range of skill levels and aspirations.

Why choose a full-on CNC milling machine learning course, you might ask? Well, the intricacies of CNC milling machines, laser cutting, and machining require hands-on experience and theoretical knowledge to ensure optimal results. While some might opt for trial and error or self-learning approaches, structured courses provide a comprehensive foundation and expert guidance to accelerate your learning curve.

Alison

This online course on Diploma in Mechanics of Machining starts with explaining the physics of the cutting process. The objective of this study is to provide an analytical basis which relates cutting forces, tool stresses, and temperature, etc. Non-traditional machining processes are now being widely used to generate intricate and accurate shapes in materials, like titanium, stainless steel and other difficult-to-machine alloys.

Coursera

The course covers various topics, including CAD software, creating 2D and 3D models, generating toolpaths using CAM software, and practical aspects of using CNC programs and machining. It offers hands-on exercises and real-world examples to reinforce the learning experience. By the end of the course, learners should have a solid grasp of CAD, CAM, and the essential skills required to master CNC programming and machining.

Udemy

The “Introduction to CNC Programming” course on Udemy is designed for individuals interested in learning CNC programming and operating computer numerical control (CNC) machines. Suitable candidates for this course include beginners who want to enter the field of CNC programming, machinists, engineers, or hobbyists looking to enhance their skills in programming CNC machines and programming.

Throughout this article, we’ll highlight the key factors to consider when selecting the best CNC courses online or technical training program and explore the benefits of pursuing formal education in this field. We’ll also delve into some of the most reputable and effective courses available today, ranging from online platforms to specialized training centers.

So, whether you’re an aspiring entrepreneur eager to bring your innovative product to life or a seasoned machine shop operator, or a former machine operator, shop operator, shop operator, and shop professional looking to enhance your skill set, join us as we delve into the world of CNC learning courses and unlock the doors to precision machining mastery. Let’s get started!

What is CNC Programming?

CNC programming involves creating instructions that direct computer numerical control (CNC) machines to execute precise machining operations. By writing code, typically in G-code, programmers specify the milling machine’s movements, tooling paths and selection, cutting parameters, and other essential details. This automated process eliminates the need for manual intervention and enables the production of complex and accurate parts.

“CNC machine programming is highly valued in industries like manufacturing, engineering, and prototyping as cutting tools, offering increased efficiency, consistency, and the ability to create intricate geometries. Mastering CNC programming courses equips individuals with the skills to operate CNC machines and unleash their creative potential in precision machining.

Proficiency in CNC programming opens up a world of opportunities, enabling individuals to optimize production processes, troubleshoot issues, and innovate in their respective fields. By staying at the forefront of technological advancements, such as multi-axis machining and CAD/CAM integration, CNC programmers can leverage the full potential of program CNC machines.

This proficiency in metalworking skills is invaluable in industries where precision and automation are crucial for success. Whether it’s milling machines, manufacturing complex components, or rapid prototyping, the CNC+ training program and programming empowers individuals to achieve higher levels of efficiency, accuracy, and creativity in the world of machining and milling machine part.

5 Factors to Consider When Choosing the Best CNC Learning Courses

When choosing the best CNC learning and online courseware, it’s important to consider several factors that will ensure you have a comprehensive and effective learning experience. Here are five key factors to consider:

- Course Content and Curriculum: Ensure the course covers essential topics like CNC machining principles, programming languages, machine setup, and troubleshooting. Look for advanced topics and industry-specific applications relevant to your interests.

- Instructor Expertise and Experience: Research instructors’ qualifications, industry experience, and teaching credentials. Experienced professionals with practical knowledge can offer valuable insights and effectively communicate complex concepts.

- Hands-on Training Opportunities: Look for courses that provide practical application opportunities, such as simulated machining exercises or access to CNC machines for practice. Hands-on training allows you to develop essential skills in machine operation, programming, and troubleshooting.

- Learning Resources and Support: Consider the availability of comprehensive learning resources and support offered by the course. Look for resources like textbooks, online materials, or a dedicated support system to enhance your learning experience.

- Flexibility and Accessibility: Evaluate the course format and delivery options. Determine if the course is offered in-person, online, or a combination of both. Consider your schedule and learning preferences to find a course that fits your needs. Additionally, check if the course offers flexible access to materials, allowing you to learn at your own pace.

Here are the Best CNC Learning Courses Reviewed Online

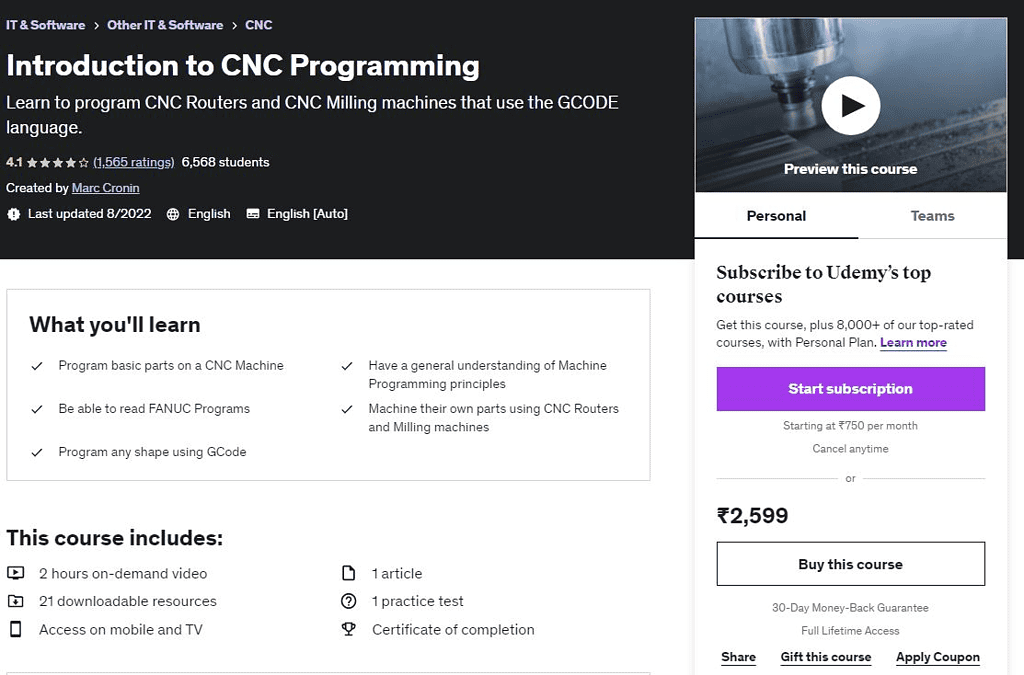

Introduction to CNC Programming

The “Introduction to CNC Programming” course on Udemy is designed for individuals interested in learning CNC programming and operating computer numerical control (CNC) machines. Suitable candidates for this course include beginners who want to enter the field of CNC programming, machinists, engineers, or hobbyists looking to enhance their skills in programming CNC machines and programming.

Who Is Suitable For This Course?

The course covers a wide range of topics, including a basic understanding of CNC machines, working with G-code, creating toolpaths, and simulating programs. It provides hands-on exercises and practical examples to reinforce the learning process. The course is also an interactive learning tool that includes downloadable resources, quizzes, and instructor support to assist students throughout their learning journey.

What Are The Features & Course Content?

- Introduction to CNC machines and their components

- G-code fundamentals and syntax

- Toolpath creation techniques

- Speed and feed calculations

- Introduction to CNC software

- Workpiece setup and tooling considerations

- Common machining operations

- Troubleshooting and error handling

What’s the Duration And Price?

The duration of the course may vary depending on the learner’s pace, but it typically takes around 5-6 hours to complete online training package. As for the price of training courses, it is $15.99 and check the Udemy website for the most up-to-date information on online training courses here, as prices may vary over time.

Pros:

- A comprehensive introduction to CNC programming concepts and techniques.

- Practical examples and exercises for hands-on learning.

- Instructor support and downloadable resources for enhanced understanding.

- Self-paced learning allows flexibility to fit the course into individual schedules.

- Lifetime access to course materials, enabling learners to revisit the content as needed.

Cons:

- Lack of hands-on experience with actual CNC machines, as it is an online course.

- Limited interactivity compared to in-person training.

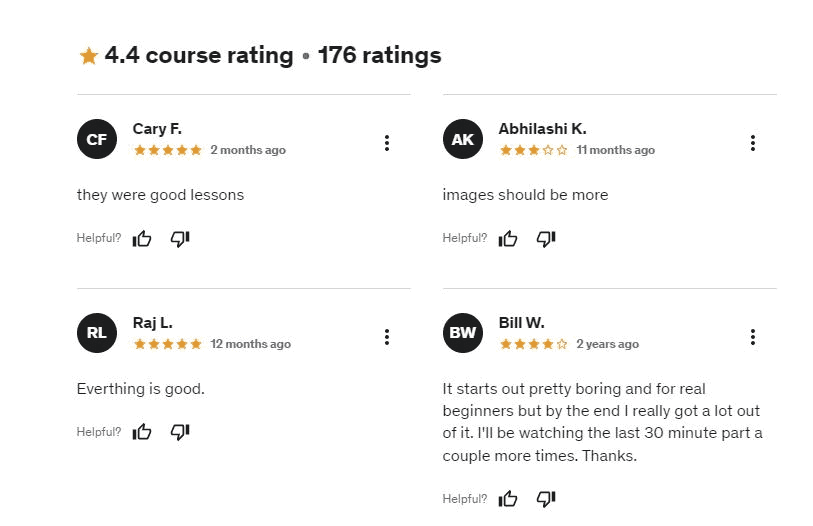

Customer Review:

I recently completed the “Introduction to CNC Programming” course, and I found it to be extremely helpful. The instructor explained all the courses’ concepts clearly and provided practical examples that made it easy to understand and apply. The downloadable resources were valuable references, and the quizzes helped reinforce my knowledge. The self-paced format allowed me to learn at my own speed. Overall, it’s a great course for beginners or anyone looking to improve their CNC programming skills. I highly recommend it!

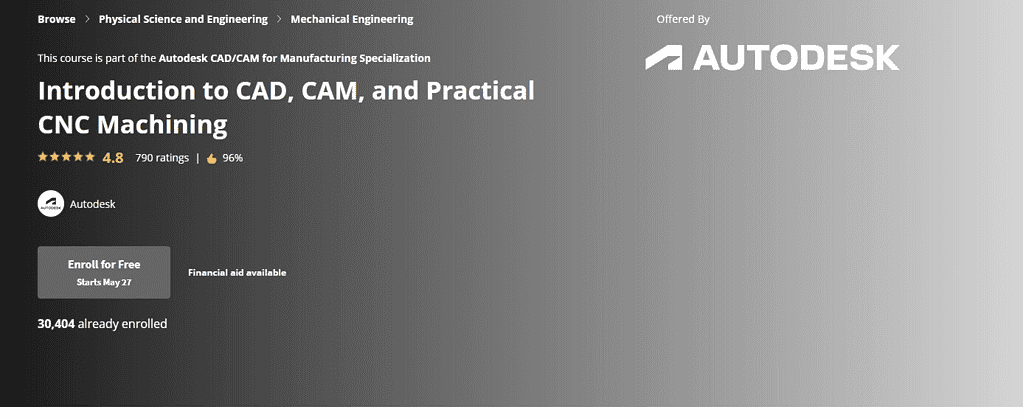

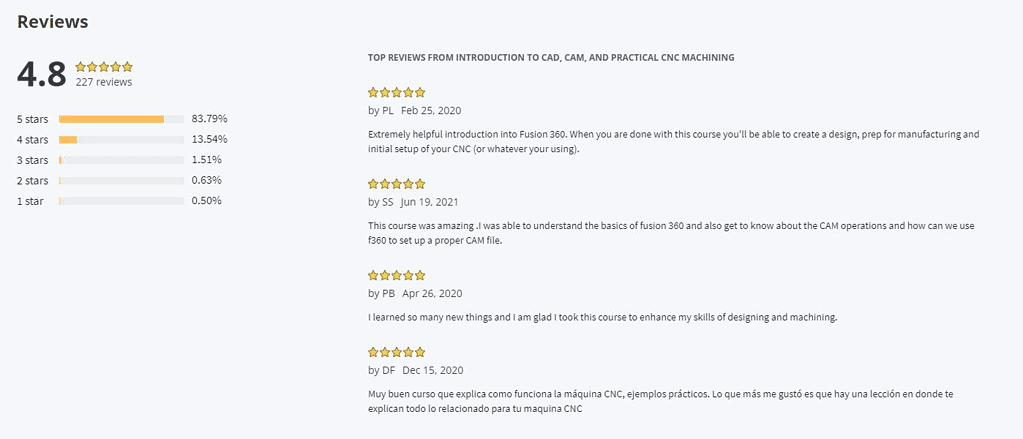

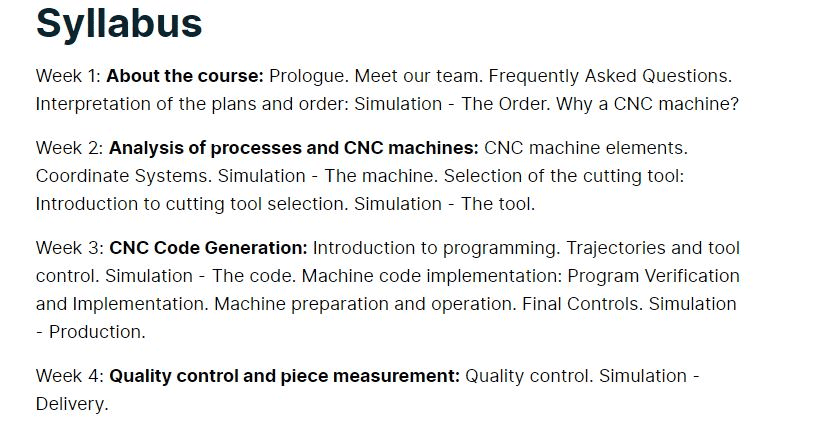

Introduction to CAD, CAM, and Practical CNC Machining

The course “Introduction to CAD, CAM, and Practical CNC Machining,” available on Coursera, aims to provide learners with a comprehensive understanding of Computer-Aided Design (CAD), Computer-Aided Manufacturing (CAM), and practical CNC machining.

Who Is Suitable For This Course?

It is suitable for individuals interested in gaining foundational knowledge in these areas and those seeking to enhance their skills in CNC machining.

What Are The Features & Course Content?

The course covers various topics, including CAD software, creating 2D and 3D models, generating toolpaths using CAM software, and practical aspects of using CNC programs and machining. It offers hands-on exercises and real-world examples to reinforce the learning experience. By the end of the course, learners should have a solid grasp of CAD, CAM, and the essential skills required to master CNC programming and machining.

What’s the Duration And Price?

The duration of the course is typically around four weeks, with an estimated time commitment of 4-6 hours per week. As for the price, Coursera offers both a free audit option and a paid enrollment option, which provides additional benefits like graded assignments and a shareable certificate upon completion of all the cycles.

Pros:

- The course provides a thorough introduction to CAD, CAM, and CNC machining, covering both theoretical concepts and practical applications.

- The inclusion of hands-on exercises allows learners to apply their knowledge and gain practical experience with CNC machining.

- Coursera offers the flexibility to learn at your own pace, making it suitable for individuals with busy schedules.

- The course is hosted on the reputable Coursera platform, known for its high-quality content and user-friendly interface.

- The skills acquired in this course are directly applicable to various industries, making them valuable for career advancement.

Cons:

- As an introductory course, it may not delve into advanced or specialized topics in CAD, CAM, or CNC machining.

- Online courses may lack the same level of interaction and personalized feedback as in-person training.

Customer Review:

I recently completed the “Introduction to CAD, CAM, and Practical CNC Machining” course on Coursera, and I found it to be an excellent starting point for beginners in the field. The course provided a clear and structured introduction to CAD and CAM, along with practical exercises that helped solidify my understanding. The instructor’s explanations were easy to follow, and the course materials were well-organized. However, I wished the course delved a bit deeper into certain topics. Overall, I highly recommend this course to anyone looking to gain a fundamental understanding of CAD, CAM, and CNC machining.

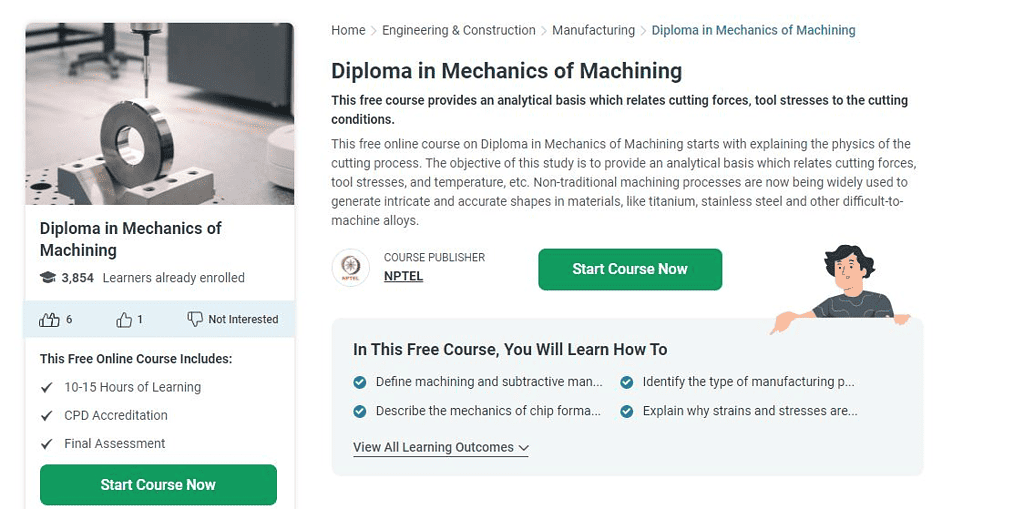

Diploma in Mechanics of Machining

The Advanced Diploma in Mechanics of Machining, available on Alison, is a comprehensive training program designed to provide learners with in-depth knowledge and skills in the field of machining.

Who Is Suitable For This Course?

This course is suitable for individuals interested in pursuing a career in machining or those looking to enhance their existing knowledge in the field. It is ideal for aspiring machinists, engineers, or anyone seeking to gain a solid understanding of machining principles.

What Are The Features & Course Content?

The course covers a wide range of topics, including cutting tools, machine tools, machining processes, precision measurements, and machining strategies. It offers a comprehensive exploration of the mechanics behind various machining techniques and provides learners with practical insights into machine types and applications.

What’s the Duration And Price?

The duration of the course is self-paced, allowing learners to study at their own convenience. The course is available for free on Alison, making it accessible to a broad audience without any financial barriers.

Pros:

- The course covers various topics related to machining, providing learners with a thorough understanding of the subject.

- The flexibility of self-paced learning allows individuals to study at their own convenience, fitting it into their busy schedules.

- The course focuses on practical skills and knowledge that are highly relevant to the machining industry, offering valuable insights for career advancement.

- The course is available for free on Alison, making it accessible to a broader audience, eliminating financial constraints.

- Successful completion of the course allows learners to obtain an Alison diploma, which can enhance their credentials and career prospects.

Cons:

- As an online course, the level of interaction with instructors or peers may be limited compared to traditional classroom settings.

- The course primarily focuses on theoretical aspects, and learners may need to seek additional opportunities to gain hands-on experience with machining equipment.

Customer Review:

I recently completed the Advanced Diploma in Mechanics of Machining on Alison, and I must say it exceeded my expectations. The course covered a wide range of topics covered, providing a comprehensive understanding of machining principles. The content was well-structured, and the explanations were clear and concise. While the lack of hands-on experience was a downside, I appreciated the flexibility of self-paced learning. Overall, I highly recommend this course to anyone looking to delve into the mechanics of machining and gain industry-relevant skills.

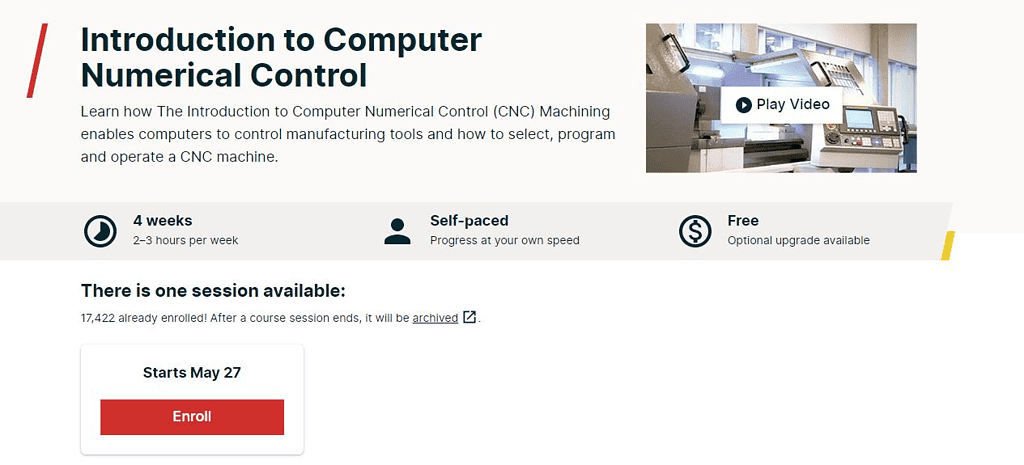

Introduction to Computer Numerical Control

The course “Introduction to Computer Numerical Control” is available on edX. It is designed to provide learners with a comprehensive understanding of Computer Numerical Control (CNC) technology and its applications in various industries.

Who Is Suitable For This Course?

This course is suitable for individuals interested in pursuing a career in CNC machining, as well as professionals in manufacturing, engineering, or related fields who want to enhance their knowledge of CNC technology. It is ideal for beginners who want to learn the fundamentals of CNC milling machine programming.

What Are The Features & Course Content?

The course covers a range of topics, including CNC machine operations, programming, tooling, and work-holding techniques. It provides learners with a solid foundation in CNC technology and its practical applications. The course features interactive lessons, quizzes, and hands-on exercises to reinforce the learning experience.

What’s the Duration And Price?

The course is self-paced, allowing learners to study at their own convenience. The estimated time commitment is around 4-6 hours per week. It is available for free, with the option to upgrade to a verified certificate for a fee.

Pros:

- The course covers essential topics related to CNC technology, providing a thorough understanding of its principles and applications.

- The course incorporates interactive lessons, quizzes, and hands-on exercises, enhancing the learning experience.

- The self-paced format allows learners to study at their own pace, accommodating different schedules and commitments.

- The course emphasizes the practical applications of CNC technology, equipping learners with real-world skills.

- The course is available for free, making it accessible to a wide range of learners.

Cons:

- As an online course, the level of interaction with instructors or peers may be limited compared to in-person training.

- Although the course includes hands-on exercises, learners may need additional resources to gain extensive practical experience with CNC machines.

Customer Review:

I recently completed the “Introduction to Computer Numerical Control” course on edX, and I found it to be an excellent introduction to CNC technology. The course content was comprehensive, covering all the necessary aspects of CNC machining. The interactive lessons and quizzes helped reinforce my understanding, and the hands-on exercises provided practical experience. The self-paced format allowed me to fit the course into my schedule effectively. Overall, I highly recommend this course to anyone interested in learning about CNC technology and its applications.

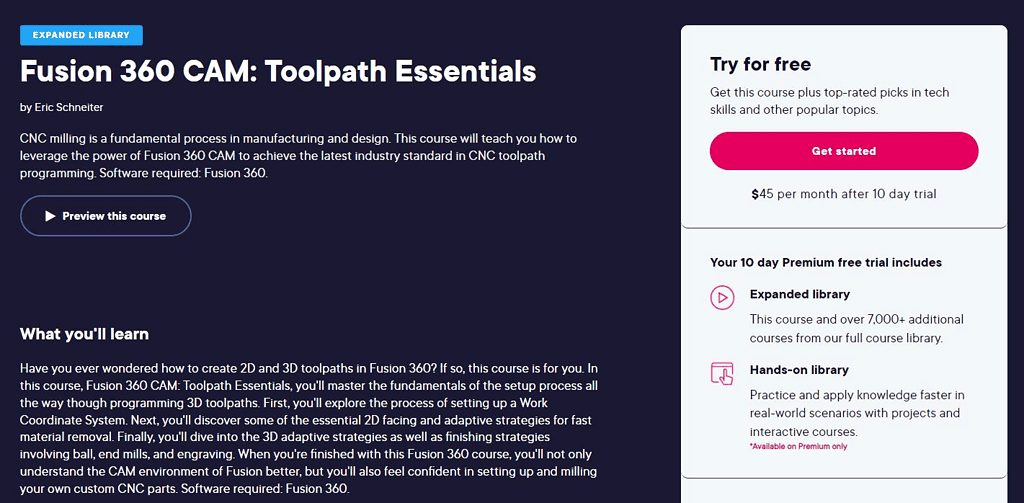

Fusion 360 CAM: Toolpath Essentials

The course “Fusion 360 CAM Toolpath Essentials” is available on Pluralsight. It is designed to provide learners with a comprehensive understanding of Fusion 360’s Computer-Aided Manufacturing (CAM) capabilities and the essentials of creating toolpaths.

Who Is Suitable For This Course?

This course is suitable for individuals who are familiar with Fusion 360 and want to expand their knowledge of CAM toolpaths. It is ideal for designers, engineers, or anyone involved in CNC machining or manufacturing processes.

What Are The Features & Course Content?

The course covers a wide range of topics, including CAM setup, creating toolpaths, setting cutting strategies, simulation, and post-processing. It provides practical examples and demonstrations to help learners gain hands-on experience with Fusion 360’s CAM capabilities.

What’s the Duration And Price?

The course duration is approximately 2 hours and 12 minutes. Pluralsight offers a subscription-based pricing model, where users can access this course and other courses in their library with a monthly or annual subscription fee.

Pros:

- The course provides comprehensive coverage of Fusion 360’s CAM capabilities, including toolpath creation and cutting strategies.

- The inclusion of practical examples and demonstrations helps learners understand and apply the concepts effectively.

- The course allows learners to gain hands-on experience with Fusion 360’s CAM tools, enhancing their proficiency.

- With a Pluralsight subscription, learners can access not only this course but also a wide range of other courses, providing value for the investment.

- The self-paced nature of the course allows learners to study at their own convenience, fitting it into their busy schedules.

Cons:

- This course assumes prior familiarity with Fusion 360, so beginners may need to complete introductory courses before diving into the CAM toolpath essentials.

- While the subscription model provides access to multiple courses, it may not be suitable for learners seeking a one-time purchase option.

Customer Review:

I recently completed the “Fusion 360 CAM Toolpath Essentials” course on Pluralsight, and it was exactly what I needed to expand my Fusion 360 skills. The course provided a comprehensive overview of CAM toolpaths in Fusion 360, and the practical examples helped solidify my understanding. The instructor’s explanations were clear, and the course materials were well-structured. The subscription-based pricing of Pluralsight offers great value, as I can access this course and many others. Overall, I highly recommend this course to anyone looking to enhance their Fusion 360 CAM skills.

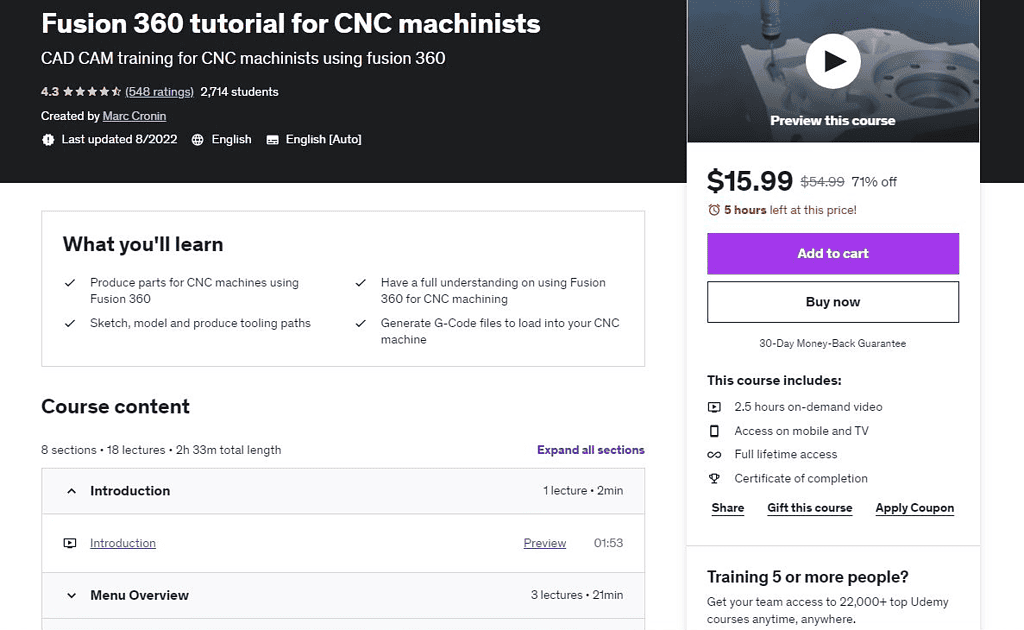

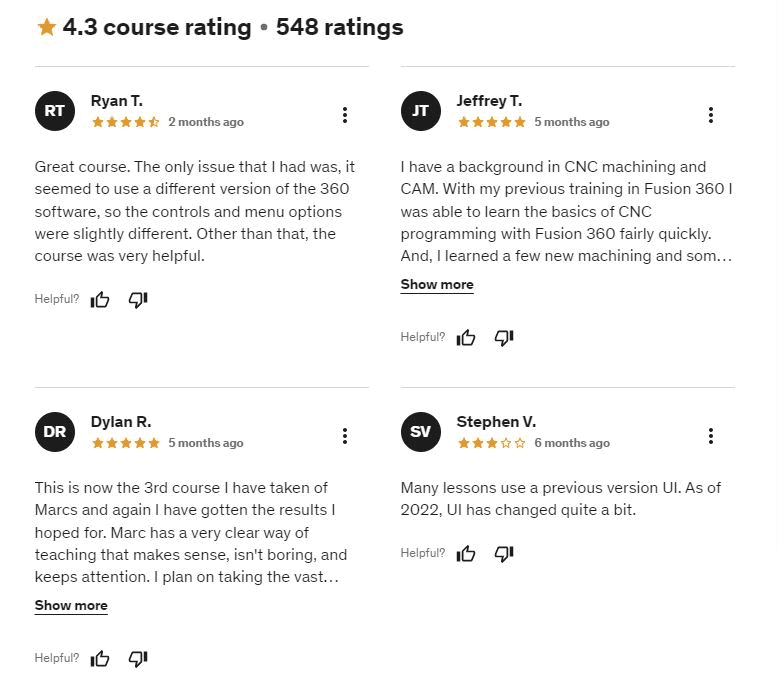

Fusion 360 tutorial for CNC machinists

The course “Fusion 360 Tutorial for CNC Machinists” is available on Udemy. It is specifically designed for CNC machinists who want to learn how to use Fusion 360 for their machining projects.

Who Is Suitable For This Course?

This course is suitable for CNC machinists who have basic knowledge of machining operations and want to enhance their skills by incorporating Fusion 360 into their workflow. It is also beneficial for engineers, designers, or anyone interested in CNC machining and Fusion 360.

What Are The Features & Course Content?

The course covers a wide range of topics, including Fusion 360 interface, sketching, 2D and 3D modeling, creating toolpaths, simulation, and generating G-code. It provides hands-on exercises and real-world examples to help learners apply their knowledge in practical CNC machining scenarios.

What’s the Duration And Price?

The course duration is approximately 7 hours and 45 minutes, divided into video lectures and exercises. The price of the course may vary on Udemy, as they often have promotional discounts and sales. It is recommended to check the Udemy website for the most up-to-date pricing information.

Pros:

- The course is tailored specifically for CNC machinists, providing practical knowledge and skills applicable to their profession.

- The course covers various aspects of Fusion 360, including sketching, modeling, toolpath creation, and G-code generation.

- The inclusion of hands-on exercises allows learners to practice and reinforce their skills in real-world scenarios.

- Once enrolled, learners have lifetime access to the course materials, allowing them to revisit the content whenever needed.

- The course instructor provides support and answers questions, creating a supportive learning environment.

Cons:

- Basic Machining Knowledge Required: This course assumes a basic understanding of CNC machining concepts, so individuals with no prior knowledge may need to seek introductory resources.

- Limited Interactivity: As an online course, the level of interaction with the instructor may be limited compared to in-person training.

Customer Review:

I recently completed the “Fusion 360 Tutorial for CNC Machinists” course on Udemy, and it exceeded my expectations. The course provided a comprehensive overview of Fusion 360 and its application in CNC machining. The instructor’s explanations were clear, and the hands-on exercises helped solidify my understanding. The lifetime access to the course materials is a great advantage, as I can revisit them whenever needed. Overall, I highly recommend this course to CNC machinists looking to incorporate Fusion 360 into their workflow.

Manufacturing Process with Autodesk Fusion 360

The course “Manufacturing Process with Autodesk Fusion 360,” available on Coursera, is designed to provide learners with a comprehensive understanding of Autodesk Fusion 360 and its application in the manufacturing process.

Who Is Suitable For This Course?

This course is suitable for individuals interested in learning about the manufacturing process using Autodesk Fusion 360. It is ideal for engineers, designers, and anyone involved in product development or manufacturing industries.

What Are The Features & Course Content?

The course covers various topics, including 3D modeling, simulation, toolpath generation, and CNC machining. It provides hands-on exercises and real-world examples to help learners apply their knowledge to manufacturing processes. The course also focuses on collaboration and data management, ensuring that learners gain practical skills for effective teamwork.

What’s the Duration And Price?

The course duration is typically around four weeks, with an estimated time commitment of 4-6 hours per week. Coursera offers both a free audit option and a paid enrollment option, which provides additional benefits like graded assignments and a shareable certificate upon completion.

Pros:

- The course provides a comprehensive overview of Autodesk Fusion 360 and its application in the manufacturing process.

- The inclusion of hands-on exercises allows learners to apply their knowledge and gain practical experience with Fusion 360.

- The course emphasizes collaboration and data management, essential skills for effective teamwork in manufacturing processes.

- The self-paced format allows learners to study at their own pace, fitting it into their busy schedules.

- Coursera is a reputable platform known for its high-quality courses and user-friendly interface, enhancing the learning experience.

Cons:

- The course assumes some prior knowledge of Autodesk Fusion 360 or 3D modeling, so beginners may need to familiarize themselves with the basics before taking this course.

- As an online course, the level of interaction with instructors may be limited compared to in-person training.

Customer Review:

I recently completed the “Manufacturing Process with Autodesk Fusion 360” course on Coursera, and it was an excellent learning experience. The course provided a comprehensive understanding of Fusion 360 and its application in the manufacturing process. The hands-on exercises were challenging yet rewarding, allowing me to apply my knowledge in practical scenarios. The course materials were well-structured, and the video lectures were clear and engaging. Overall, I highly recommend this course to anyone interested in learning about Fusion 360 and its role in the manufacturing process.

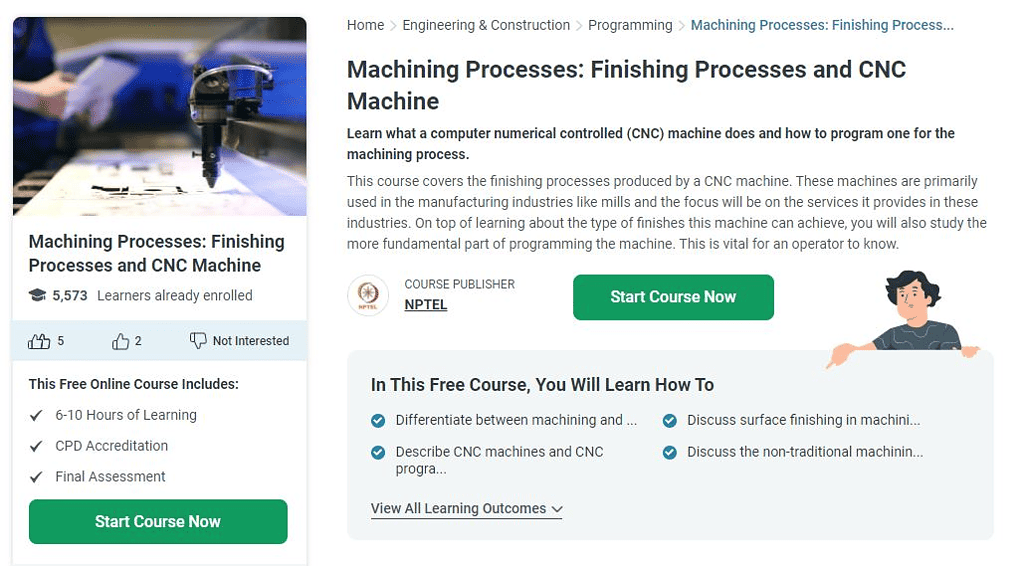

Machining Processes: Finishing Processes and CNC Machine

The course “Machining Processes: Finishing Processes and CNC Machine,” available on Alison, is designed to provide learners with a comprehensive understanding of finishing processes in machining and the use of CNC machines.

Who Is Suitable For This Course?

This course is suitable for individuals interested in gaining knowledge and skills in machining processes, specifically focusing on finishing processes and CNC machines. It is ideal for students, technicians, machinists, or anyone involved in manufacturing or related industries.

What Are The Features & Course Content?

The course covers various topics, including types of finishing processes, surface roughness, cutting tool selection, and CNC machine operations. It provides detailed explanations, practical examples, and interactive quizzes to reinforce learning. Learners will acquire essential knowledge to perform finishing processes effectively and operate CNC machines.

What’s the Duration And Price?

The course is self-paced, allowing learners to complete it at their own convenience. The duration may vary depending on the individual’s learning speed and commitment. Alison offers free access to the course content, with the option to purchase a certificate upon completion for an additional fee.

Pros:

- The course provides a comprehensive understanding of finishing processes in machining and the use of CNC machines.

- The inclusion of practical examples helps learners apply their knowledge to real-world machining scenarios.

- The interactive quizzes assess learners’ understanding and reinforce key concepts.

- The self-paced format allows learners to study at their own convenience, fitting it into their schedule.

- The course content is available for free, making it accessible to a wide range of learners.

Cons:

- As an online course, the level of interaction with instructors may be limited compared to in-person training.

- While the course content is free, there is an additional fee for obtaining a certificate, which may be a consideration for some learners.

Customer Review:

I recently completed the “Machining Processes: Finishing Processes and CNC Machine” course on Alison, and it was a valuable learning experience. The course provided a comprehensive overview of finishing processes and CNC machines, covering important topics and techniques. The practical examples and interactive quizzes helped solidify my understanding. Although there were limitations in instructor interaction, the course materials were well-presented and easy to follow. I appreciate the free access to the course content, which allowed me to expand my knowledge at my own pace. Overall, I highly recommend this course to individuals looking to enhance their understanding of machining processes.

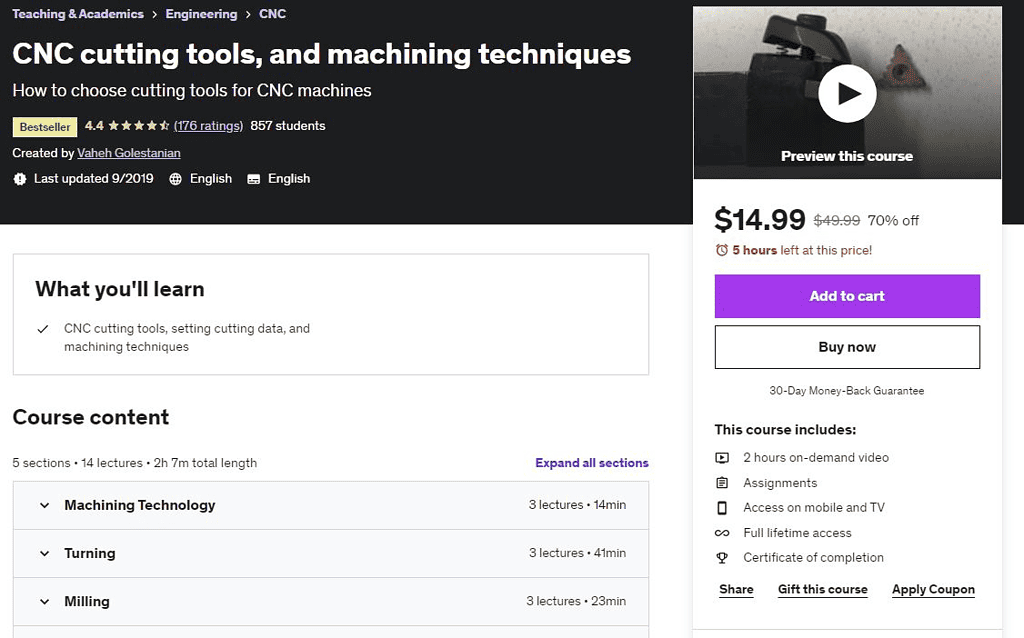

CNC cutting tools and machining techniques

The course “CNC Cutting Tools and Machining Techniques,” available on Udemy, is designed to provide learners with a comprehensive understanding of CNC cutting tools and various machining techniques.

Who Is Suitable For This Course?

This course is suitable for individuals involved in CNC machining, such as machinists, engineers, or anyone interested in expanding their knowledge of CNC machinists, cutting tools, and machining techniques. It is beneficial for beginners as well as those with some prior experience in CNC machining.

What Are The Features & Course Content?

The course covers a wide range of topics, including different types of various CNC routers, cutting tools, their applications, cutting tool materials, machining parameters, and machining techniques. It provides detailed explanations, visual demonstrations, and practical examples to help learners grasp the concepts effectively.

What’s the Duration And Price?

The course duration is approximately 3 hours, divided into video lectures and demonstrations. The price of the course may vary on Udemy, as they often have promotional discounts and sales. It is recommended to check the Udemy website for the most up-to-date pricing information.

Pros:

- The course provides a comprehensive understanding of CNC cutting tools and various machining techniques.

- Visual demonstrations and practical examples help learners see the concepts in action.

- The instructor provides clear and concise explanations, making complex topics easier to understand.

- The course is relatively short, allowing learners to acquire essential knowledge in a concise timeframe.

- Once enrolled, learners have lifetime access to the course materials, enabling them to revisit the content whenever needed.

Cons:

- This course assumes a basic understanding of CNC machining concepts, so individuals with no prior knowledge may need to seek introductory resources.

- As an online course, the level of interaction with the instructor may be limited compared to in-person training.

Customer Review:

I recently completed the “CNC Cutting Tools and Machining Techniques” course on Udemy, and it exceeded my expectations. The course provided a comprehensive overview of CNC cutting tools and machining techniques, covering important topics in a clear and concise manner. The visual demonstrations and practical examples were particularly helpful in solidifying my understanding. The lifetime access to the course materials is a great advantage, as I can revisit them whenever needed. I highly recommend this course to anyone looking to enhance their knowledge of CNC cutting tools and machining techniques.

Frequently Answered Questions

- What are the top-rated CNC learning courses available?

The top-rated CNC learning courses can vary depending on individual preferences and requirements. It’s recommended to research and read reviews to find courses with positive feedback and high ratings from reputable sources.

- How do I choose the best CNC learning course for my skill level and goals?

To choose the best CNC learning course, consider your skill level, whether you are a beginner or have some prior experience. Also, assess your specific goals, such as learning CNC programming, machine operation, or advanced machining techniques. Look for courses that align with your skill level and cover the topics that interest you.

- Can I learn CNC machining online, or should I consider in-person training?

CNC machining can be learned both online and through in-person training. Online courses offer flexibility and convenience, allowing you to learn at your own pace and from anywhere. In-person training provides hands-on experience and direct interaction with instructors. Consider your learning style, schedule, and access to resources when deciding between online or in-person training.

- What type of equipment or software do I need to participate in a CNC learning course?

The equipment and software requirements can vary depending on the specific course. Basic requirements may include a computer with internet access and CAD/CAM software, while more advanced courses may require access to a CNC machine for hands-on practice. Review the course details or reach out to the course provider for specific equipment and software requirements.

- Are there any financial assistance options, such as scholarships or discounts, available for CNC learning courses?

Some CNC learning courses or platforms may offer financial assistance options such as scholarships, discounts, or payment plans. Research and inquire about any available financial assistance options from the course provider or platform. Additionally, check if your employer or local organizations offer funding or reimbursement programs for professional development courses.

- What are the essential G code programs used in CNC lathe programming?

In CNC lathe programming, G code programs play a crucial role. These programs include commands such as G00 for rapid positioning, G01 for linear interpolation, G02/G03 for circular interpolation, and G96/G97 for constant surface speed control. Understanding and utilizing these G code programs is essential for effective CNC lathe programming.

- How can I utilize canned cycles and cutter compensation in CNC lathe operations?

Canned cycles are pre-programmed routines that simplify common machining operations on program CNC lathes. They automate processes such as drilling, tapping, and threading, reducing programming time and effort. Cutter compensation, on the other hand, adjusts the tool’s position relative to the workpiece to account for tool diameter. By incorporating canned cycles and cutter compensation in CNC lathe operators can streamline production and achieve accurate machining results.

- What is the significance of datum usage and plane selection in CNC turning?

In CNC turning, datum usage refers to the selection of a reference point or surface for establishing measurement and positioning. It ensures consistency and accuracy in machining operations. Plane selection involves determining the plane of motion for the tool during turning operations, such as X-Z or X-Y planes. Proper datum usage and plane selection are vital for precise and repeatable CNC turning processes.

- Where can I find the latest blog posts and resources on CNC lathe programming and G code programming?

To access the latest blog posts and resources on CNC lathe programming and G code programming, you can visit websites such as DIY CNC Cookbook, G Code Tutor, or the blog section of the National Institute for Metalworking Skills (NIMS). These platforms provide valuable insights, tutorials, and updates to enhance your knowledge and skills in CNC lathe programming.

- Are there any recommended CNC courses or classes available to learn G code programming and program drilling cycles on CNC lathes?

Yes, there are several recommended CNC classes available to learn and write G code programming and program drilling cycles on CNC lathes. Platforms such as Udemy, Coursera, and the CNC Cookbook offer comprehensive CNC courses and classes suitable for beginners and experienced operators. These courses cover topics like G code programming, drilling cycles, program layout, and CNC lathe operations, equipping learners with the necessary skills for successful CNC lathe programming.

Conclusion:

In conclusion, finding the best CNC training and learning course depends on your individual needs, skill level, and goals. Whether you’re a beginner looking to acquire foundational knowledge or an experienced professional seeking to enhance your own CNC training and machining skills, there are numerous courses available to suit your requirements. Consider factors such as course content, instructor expertise, reviews, and ratings, duration, and affordability when making your decision.

Remember to prioritize hands-on practice, comprehensive coverage of various CNC training principles and techniques, and the availability of certifications or credentials. By investing in the right CNC training and learning course, you can gain the knowledge and skills needed to excel in the field of CNC training and machining and propel your career forward.

Richa Sharma is a research content writer for over 10 years. She has a vast amount of experience in many different industries and has written for both small and large companies. Her specialty is creating compelling, engaging, and informative content that engages the reader and drives conversions. When it comes to writing, she has a knack for taking complex topics and making them easy to understand for the average reader. We are Excited to have Richa onboard with us here at https://financialnomads.com

Other Courses you might like to review

http://financialnomads.com/best-solar-industry-courses/

http://financialnomads.com/best-project-management-courses/